Pipe Threading Machine User Guide – Definitions

Definitions

Annealing

The process of reducing the hardness of a metal by heating it and allowing it to cool slowly.

Bearing

That portion of the profile face of the die which rides against the part being threaded. In a new die which cuts ahead of center it is the distance from the cutting edge of the die segment to the tangent point between the die segment and the work piece.

Beveling

Angle cut on end of material, often used to prepare pipe for welding. The most common angles are 30, 37.5, and 45 degrees.

Chamfer

To remove sharp corner on outside end of material.

Chasers

See Dies.

Coolant

See Cutting Fluid.

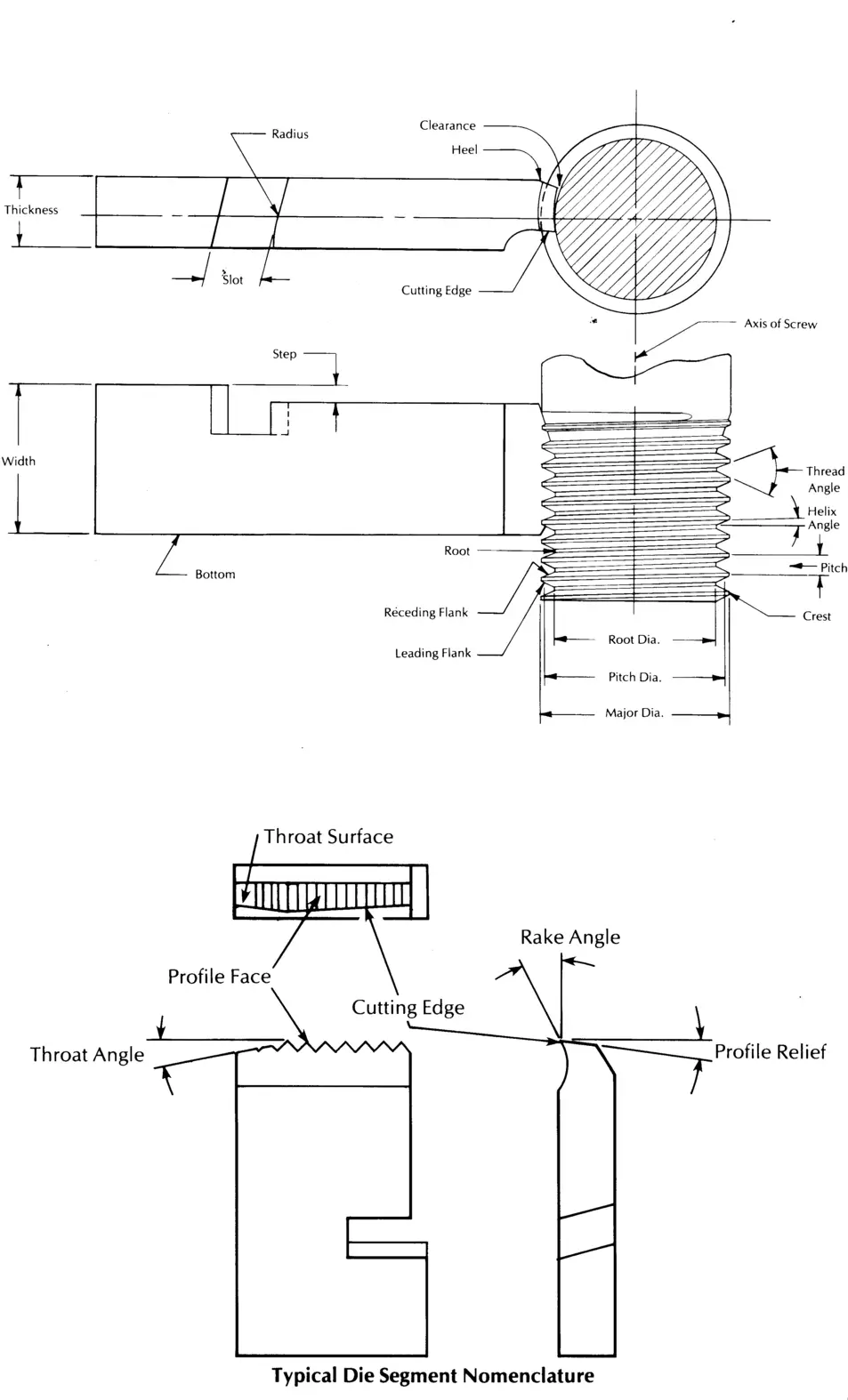

Crest

The top surface joining the two sides or flanks of a thread at the major diameter.

Cutoff - Blade Type

A narrow piece of tool steel sharpened to remove material as it is being forced into the pipe or bolt. It can be used on all types of threaded material.

Cutoff - Roller Type

A hardened roller with a knife-like edge that is forced through the wall of pipe or tubing while rotating. No material is removed, just displaced. This type of cutoff is for pipe only(sch 40 and thinner), it will not cut bolt stock or any material which tends to work harden. This includes most common stainless steels and many alloys.

Cutting Fluid

Liquid applied to material and dies while cutting threads. Not to be confused with lubricating oils, thread cutting fluids are chosen for their lubricity, thermal characteristics and anti-weld abilities.

Die Bushing

A slotted cylindrical steel support, placed in the center of a stationary die head, to support the dies when cutting smaller diameter bolts and pipe.

Die Head - Rotating

Die holder that rotates while the material to be threaded is held stationary.

Die Head - Stationary

Die holder which is fixed to the bed of the machine. The material to be threaded rotates inside the head as the die head moves over the stock. Slide In Die Heads are attached to the machine carriage by means of guides. Swing Over Die Heads are fixed in such a manner as to allow the head to be swung out of the way while still attached to the machine carriage.

Dies

A variable number of hard steel inserts with correct tooth form to produce threads. Dies can be either radial, (c.f.) or tangential. Radial dies can be either hobbed or milled form. This term when used in threading is interchangeable with the term "chaser".

Flank

The side of a thread; the surface connecting crest and roots.

Helix Angle

The angle formed between the thread profile and a plane normal to the center axis of the thread. Defined as the arctangent of the pitch divided by the pitch line circumference. The helix angle increases with increasing pitch and decreases with increasing diameter.

Hobbed Dies

Dies which are manufactured using a hob rather than a milling cutter to generate the required profile. This type of die is recognizable in that the surface which has the profile has a distinct curvature.

Jaws

Moving part of vise or chuck that adjusts to grip different size material.

Jaw Inserts

Consumable part of jaws, usually hardened and serrated.

Lead

The distance a screw thread advances axially in one turn. On a single threaded screw, the lead and pitch are identical; on a double-thread screw, the lead is twice the pitch; on a triple-thread screw, the lead is three times the pitch, etc.

Lead Screw

An attachment to a threading machine that mechanically feeds the die head and carriage along to maintain perfect lead.

Major Diameter

The largest diameter of a straight screw thread, at the crest. Major diameter replaces the term "outside diameter".

Milled Dies

Chasers which are manufactured using a milling cutter to generate the required profile of the cutting surface. This type of die is recognizable in that it has a profile which is made up of straight planes.

Minor Diameter

The smallest diameter of a straight screw thread at the root. Minor diameter replaces the term "root diameter".

Move

The amount by which the profile on a given die is offset from the segment preceding or following it. For equally spaced die segments, this distance is the pitch divided by the number of segments in a set.

Motor - Induction

Constant speed single or three phase electric motor with many variations and combinations of load, torque, duty cycle, speed, etc.

Motor - Universal

Single phase, brush type motor, small in size. Will operate on AC or DC current. This type of motor increases the amount of horsepower available as the torque increases and the speed slows down. Slow rpm due to high torque for short durations are not detrimental.

Pitch

The distance from a point on a screw thread to a corresponding point on the next thread measured parallel to the axis.

Pitch Diameter

On a straight thread, the pitch diameter is the diameter of an imaginary cylinder, co-axial to the center of the thread, the surface of which would pass through the thread profiles at such points as to make the width of the groove equal to one-half of the basic pitch. On a taper thread, the pitch diameter at a given position on the thread axis is the diameter of the pitch cone at that position.

Radial Dies

Those dies which stand out radially from the work piece during the operation. They have a built-in bearing and helix angle and are only adjustable with respect to diameter. They are much easier to set up than tangential dies, but do not have as long a life expectancy. They are more difficult to sharpen than tangential dies.

Rake Angle

The angle which the cutting surface makes with respect to the body of the die. It is related to the "sharpness" of the die.

Root

The bottom surface joining the two sides or flanks of a thread at the minor diameter.

Tangential Dies

Dies which are manufactured so that they can be adjusted with respect to bearing, helix and diameter. These dies are typically used for long production runs. They are easier to sharpen but more difficult to set up than radial dies.

Throat

That portion of a die segment which first engages the material to be threaded. The throat is designed to machine the material to the major diameter in a series of cuts as the dies move over the material.