Why Choose Oster?

Oster provides the best pipe and bolt threading machines on the market.

Oster has been supplying high-quality, durable threading machines since 1893. 100% American-made and manufactured, we prioritize excellence, longevity, and customer satisfaction. Quality is our primary goal, and we are constantly looking for ways to improve our equipment to ensure it lasts long into the future.

We look forward to working with you to supply the highest-quality threading machines on the market. Contact us today to get started!

What Makes Oster Special?

We’re glad you asked! Oster is proud of our efforts to provide the best threading machine assistance in the industry.

Product Longevity

Oster pipe and bolt threading machines have been engineered to withstand the rigors of production environments for decades. We aim for you to buy one machine that will last for generations. This mindset of quality and longevity influences our process every step of the way. Oster threading machines will perform reliably when you need them for years.

Simplicity

Our threading machines are simple to run. No certification or CNC training is required to operate our machines. With a few hours of training, anyone can master an Oster pipe and bolt threading machine. They are user-friendly with straightforward operation.

Service-Oriented

At Oster, we value the customer. When you call Oster, a person is always on the other end of the phone. Our trained specialists are on call to provide support or training over the phone whenever you need. No matter the question or the age of your threading machine, our dedicated technical support staff is ready to help.

Questions about special or custom applications? No worries. We are always ready to tackle an exciting project or application. We enjoy a challenge and are willing to develop custom-engineered solutions to your thread-cutting dilemma.

High-Quality Pipe And Bolt Threading Machines

Both pipe threading and bolt threading machines offer excellent machining solutions, maintaining uniformity while threading pipes. Oster threading machines are reliable and accurate, with unmatched production and power capabilities. Our industrial pipe and bolt threading machines will increase efficiency while reducing production time.

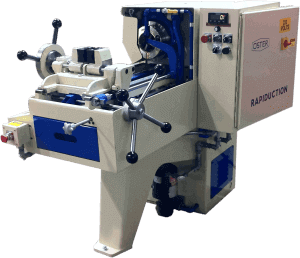

Oster 792ALX Industrial Pipe and Bolt Threading Machine

If you’re looking for the best, look no further than our 792ALX threading machine. With superior production speeds, durability, and quality, the 792ALX is the pinnacle of Oster threading machines. It can produce up to 200 threaded ends per hour and cut right and left-handed threads in a single pass. Additional features include:

- Three bed sizes

- Semi-automatic operation

- Compatible with both pipe and bolt threading

- Self-centering

- Adjustable die head

Our commitment to quality means this threading machine is affordable, made in the USA, and made to last.

Dark Thread Cutting Oil

Oster’s Superior Threading Oil (OSTO) dominates the competition. Our premium dark thread cutting oil extends the life of your dies by cooling the threads and reducing friction.

Oster “Bestoil” was our favored choice for many years, but we dug through our old records a few years ago and rediscovered our original formula. We increased the sulfur, chlorine, and animal fat content in the recipe, and OSTO now outperforms all thread cutting oil on the market.

The benefits of Oster’s dark thread cutting oil include the following:

- Increased die life

- Perfect threading

- Chip welding prevention

- Cooling lubrication

- Infinite shelf life

Industries Served by Oster

High-production pipe and bolt threading machines produce exemplary parts for several manufacturing sectors. Regardless of your industry, Oster’s selection of high-production, high-quality threading machines offers the value and longevity that makes our industrial threading solutions a worthwhile investment.

The threading machines necessary for your business will vary based on trade. Oster offers different pipe and bolt threading machines for many industries.

- Fire Sprinkler Pipe Threading: The fire sprinkler fabrication industry has long relied on Oster machines for black and galvanized pipe threading for installation in fire sprinkler systems.

- Anchor Bolt Threading: Oster threading machines can thread NC threads in a single pass with up to 25 in. thread lengths.

- Pipe And Bolt for Industrial Applications: Our pipe and bolt threading machines service many industries, including oil and gas, agricultural, manufacturing, chemical processing, and medical facilities.

- Custom Threading Machines: Our specialists are ready to help you find solutions for all custom, unusual, or complex applications.

Contact Oster Today for All Pipe And Bolt Threading Machine Services

When you work with Oster, you can rest assured that our pipe and bolt threaded machines will provide you with the best product on the market.

We are prepared to help you get started with your threading machine. Contact us with any questions or request a quote to get started today!