Pipe Threading Machine User Guide – Die Re-Sharpening / Chaser Re-Grinding

The following is intended to provide guidelines for grinding the cutting edges of chaser type threading tools. The geometry of these tools is complex and there is little room for error. These tools are expensive and because of the risk of doing damage to them during the resharpening procedure, grinding should only be done by people who are qualified. If properly done, the effective life of the die segments can be greatly extended

NEVER attempt to grind dies by hand. It is impossible to maintain the geometry of the dies without the proper tools and fixtures.

NEVER take more than is absolutely necessary from the rake surface of the die. Remove the dies from production early enough so that only .005 inch or less needs to be removed Radial Forces.

NEVER overheat the dies while grinding. If the dies show signs of discoloration due to heat, you are trying to take too deep a cut. If you do inadvertently overheat the dies, do not quench them in water. Let them cool in air slowly. Damage from overheating or quenching hot dies results in reduced hardness and surface micro cracks. Although invisible, these can result in seriously reduced life of the dies.

Grinding The Rake

The grinding of the rake surface of the chaser is done with the outside diameter of the grinding wheel. It is preferable to use a grinder which has coolant pumped to the face of the die, but the operation can be performed carefully without coolant if required. Use grinding wheels designed for grinding very hard materials with a fine grit. The chaser should be clamped in a fixture which will hold the rake surface of the die at the angle recommended by the manufacturer. Slight changes in the rake angle can be made to correct the cutting action for specific materials. It is best to consult the manufacturer before doing so. Dress the wheel so that it has a clean flat surface. Advance the wheel slowly for each pass. Many light cuts are preferable to fewer heavy ones. Always grind the segment which is in the worst shape first, and then grind all other segments to the same finished thickness.

Always take the absolute minimum of material from the die. If excessive material is removed, the bearing of the die will be destroyed and the die will no longer function. It is better to regrind the dies more often with less removal of metal each time than to wear them excessively and risk losing the bearing, breaking teeth and ruining threads. Never try to sharpen a die segment to the level of a chipped or broken tooth. If a tooth is broken, remove it using the methods described below, then sharpen the remaining teeth.

Grinding the rake of dies is more important in taper thread dies since in these dies the entire surface of the die is required to cut and will eventually dull. In bolt dies, only the teeth preceding the second full tooth are required to cut. As a result of this difference, bolt dies seldom require grinding on the rake face and then only slightly.

Grinding The Throat

With bolt or other straight thread dies, most of the sharpening is done by grinding the throat. The importance of maintaining the manufacturer’s throat and throat relief angles cannot be overstated. The throat and throat relief angles are important to the ease with which the dies operate, and the finish of the completed thread.

Set the chaser up on the grinder so that the outside diameter of the wheel will grind the exact throat and throat relief angles required. Take a very light pass and inspect to make certain that the grinding wheel is contacting the entire surface evenly. Grind the worst segment first taking only the amount of material necessary, then grind all other segments in the set to exactly the same dimension.

When you have finished, line up the segments in order as shown below. Notice that in the throat area the teeth seem to grow out of the surface from the lowest numbered segment of the highest. If the increase in depth of the teeth is evenly distributed over all of the segments you have probably done a good job.

Set of chasers with properly ground lead

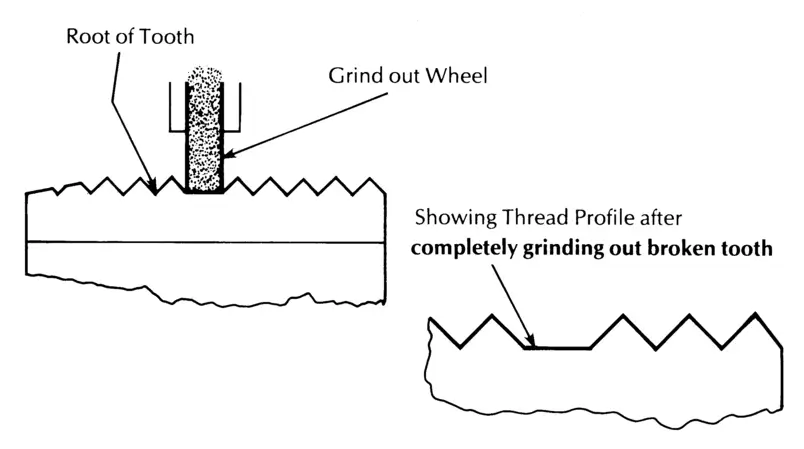

Removing Broken Or Chipped Teeth

Never attempt to grind the rake surface of the die down to the level of a chipped or broken tooth. The best method of treating a broken tooth is to remove it completely. Although this operation can be done by hand, it is best to set the chaser in a clamp on a grinding machine. Use a bonded wheel which is no wider than the pitch of the die being ground, and grind the tooth all the way to the root. Removing two adjacent teeth is not recommended, however it has been done with limited success. The cost of removing teeth makes it preferable to throwing away a set of dies.

When removing the teeth, the usual cautions about overheating the die still apply. If the die overheats, a loss of hardness or micro-cracking can result.

There are many benefits to using our pipe and bolt threading machines. By working with Oster Manufacturing, you’re investing in longevity, reliability, and support. Oster pipe threading machines are 100% American-made and manufactured using the highest quality materials. Our bolt threading machines are designed to last for generations.

Oster superior threading machines are used for numerous industrial, agricultural, fabrication, decorative, and custom applications. Our pipe threading machines offer high production for multiple industries.

Contact Oster Manufacturing to speak with our technical support staff or request a quote today to learn more about your pipe and bolt threading machine options.